Plugbuster

The PLUGBUSTER can increase well production by 50% or more!

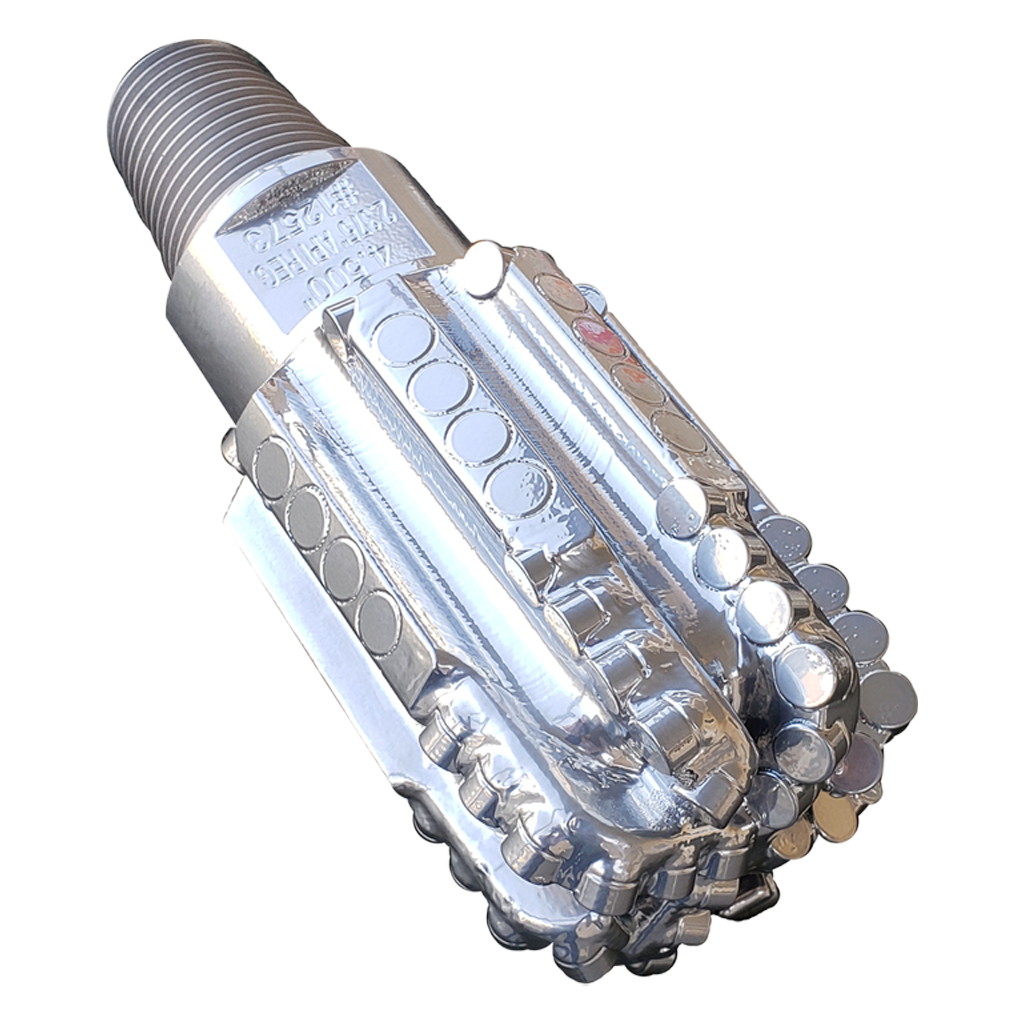

The PLUGBUSTER is the most efficient wellbore clean out tool for removing scale, cement and other solids from wellbore production casing. The tapered profile, strong one-piece construction and premium quality PDC cutters provide fast and efficient cleaning in a single trip. Our multiple-blade design ensures maximum coverage of the casing ID.

What is Plugbuster

PLUGBUSTER is an industry leading thru tubing milling tool for drilling out frac plugs, sliding sleeves and ball seats.

Wellbore cleaning is a key factor in maintaining maximum well production. Scheduled clean out operations remove accumulated solids that could lead to well under-performance.

The PLUGBUSTER is the most efficient wellbore clean out tool for removing scale, cement and other solids from wellbore production casing. The tapered profile, strong one-piece construction and premium quality PDC cutters provide fast and efficient cleaning in a single trip. Our multiple-blade design ensures maximum coverage of the casing ID.

Torquato Drilling Accessories has been in business since 1982 designing and producing our PLUGBUSTER wellbore clean out tools for customers worldwide. We can produce custom sizes from 2.650” to 10-5/8” to meet project requirements. Put our wealth of experience to work for you and allow us to show you how our PLUGBUSTER can increase your efficiency in one simple process. Cleaning top to bottom is no problem for the PLUGBUSTER.

The PLUGBUSTER can increase well production by 50% or more!

Lower Your Completion Costs With A Plugbuster Milling Bit

Torquato Drilling Accessories is an industry leader in the design and manufacture of thru tubing tools for tight oil and gas. With the development of unconventional drilling methods we immediately recognized the need for a specialized milling tool to effectively and efficiently drill out composite frac plugs used during the hydraulic fracturing process. Our engineering team developed the now famous Plugbuster for this purpose.

What Makes A Plugbuster Better

Our objective when designing the Plugbuster was to develop a milling tool that would no only drill out frac plugs but would do it better and faster than any other tool on the market. As laterals became longer it became necessary to design a tool that would not only be better but would have the strength and durability to mill out longer strings of frac plugs while producing the smallest cuttings possible. Take a look at the following features of our Plugbuster XLR:

- Solid 1-Piece Design With No Moving Parts Means No Fishing For Cones

- Tapered Profile To Engage And Smoothly Mill Away Plug Material

- Small Premium Grade PDC Cutters Positioned In A Unique Geometric Pattern To Create Smaller Cuttings

- Multiple Front Facing Flushing Ports For Effective Removal Of Cuttings

- Built-In Stabilizers With Tungsten Carbide Wear Protection Inserts

You can depend on a Plugbuster to go in the well and stay in the well until the last plug is removed. Like we say, “It Just Takes One To Get ‘R Done”

Sliding Sleeves & Frac Port Milling

Milling out sliding sleeves and frac ports presents many challenges for conventional bits and mills but not for the Plugbuster. The unique tapered design and rugged construction make our Plugbuster the ideal tool for milling our sliding sleeves and frac ports. Time and time again contractors depend on a Plugbuster to do what other bits can’t do. It’s not uncommon for a Plugbuster to mill out as many as 35 – 50 sliding sleeves or frac ports in a single run. Contact us today for more information.

There are no Features & Specifications at the moment, please try again later

A Better Milling Tool

Our objective when designing the Plugbuster was to develop a milling tool that would no only drill out frac plugs but would do it better and faster than any other tool on the market. As laterals became longer it became necessary to design a tool that would not only be better but would have the strength and durability to mill out longer strings of frac plugs while producing the smallest cuttings possible